The automotive industry is transforming through Quality 4.0, using technologies like Artificial Intelligence (AI), the Internet of Things (IoT), and Big Data to enhance efficiency and quality in production lines. This approach is making automotive assembly faster, more reliable, and reducing errors.

1. Real-Time Monitoring and Predictive Maintenance

IoT sensors monitor production machinery in real-time, checking factors like temperature and vibration to ensure everything works smoothly. Predictive maintenance uses this data to predict machine failures. For instance, a robotic arm showing increased vibration can be fixed before it breaks down, avoiding unexpected downtime.

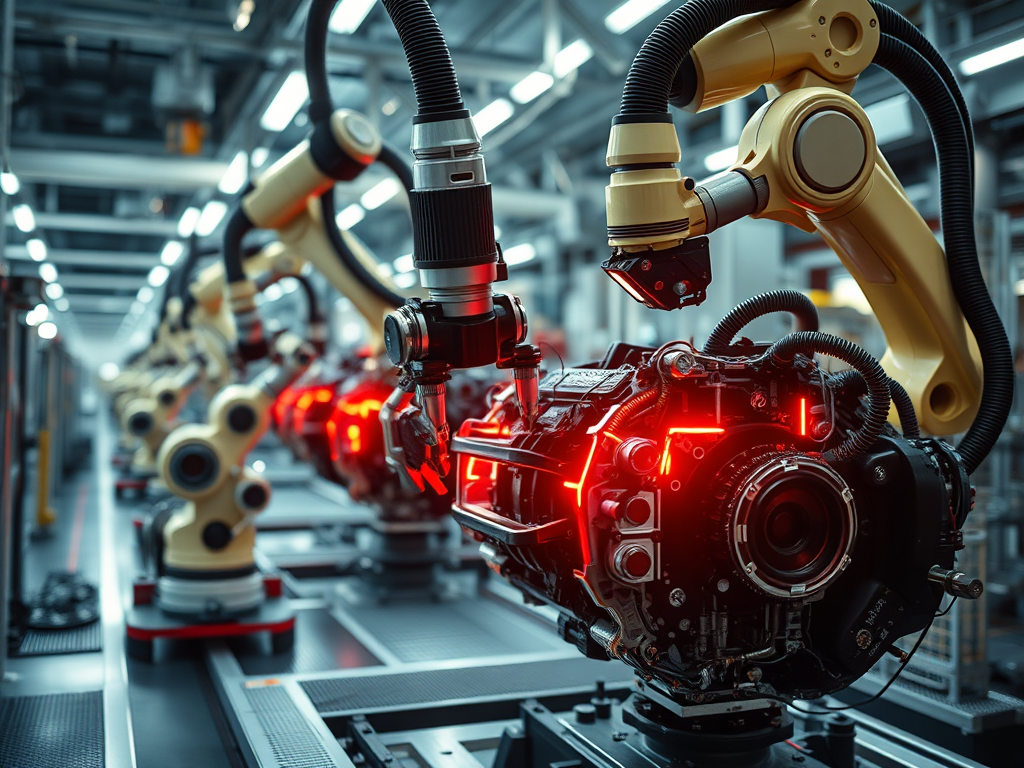

2. AI-Powered Visual Inspection

AI and computer vision help automate inspections. High-resolution cameras and AI algorithms detect defects like scratches or misaligned parts instantly, preventing faulty products from continuing down the line. This technology improves consistency and reduces human errors during inspection.

3. Digital Twins for Process Optimization

Digital twins are virtual models of production lines that allow manufacturers to simulate changes before applying them. For example, adjusting a conveyor belt’s speed in a digital twin can show its impact on quality before making real changes. This helps optimize processes without disrupting production.

4. Integrated Quality Checks with Robotics

Robots on the production line can perform assembly and quality checks simultaneously. For example, a welding robot checks the weld’s strength while it works. If a defect is found, it can adjust or alert technicians immediately, improving efficiency by reducing the need for separate quality checks.

5. Data-Driven Quality Improvements

Big Data analytics helps identify and resolve quality issues. By analyzing production data, manufacturers can find patterns that cause defects. For instance, defects occurring during specific shifts might point to machine calibration problems. Addressing these issues helps reduce recurring problems and improve overall quality.

6. Connected Worker Platforms

Connected worker platforms use wearable devices to assist production workers. These devices provide real-time instructions and alerts, helping workers avoid errors. For example, a wearable can notify a worker if they select the wrong part during assembly, ensuring tasks are completed accurately.

Conclusion

Quality 4.0 uses technologies like real-time monitoring, AI inspections, digital twins, integrated quality checks, Big Data analytics, and connected worker tools to enhance quality and efficiency in automotive production. These methods help manufacturers produce high-quality vehicles, reduce waste, and remain competitive in a fast-changing industry.

AI based

Leave a comment