This are ideas to set up a Quality System for Automotive Manufacturing and related to automotive components. It assumes the company produces internally produced components and externally sourced materials, consumables, sub-assemblies and other accessories including packaging materials. There are functions related to PURCHASING , PRODUCTION, QUALITY CONTROL, MAINTENANCE, SALES AND DELIVERY. Product Design is not considered in this system.

Incoming Inspection

Incoming inspection in automobile manufacturing is a critical process in ensuring the integrity and compliance of materials, components, and parts received from suppliers. The process involves rigorous scrutiny of each incoming item to verify its compliance to all design specifications, safety standards, and quality criteria. Components are subjected to visual inspections, measurements, material and functional tests. Any deviations or defects must be immediately identified, addressed, preventing non-conforming parts from entering the production process such as stamping, body assembling, painting and trim and final assembling. Incoming inspection is fundamental in automobile manufacturing, guaranteeing reliability and safety of vehicles, and at the same time trying to minimize defects, rework, and warranty claims.

The key objectives of an incoming inspection quality system are to:

- Check for Compliance: Ensure that incoming materials or parts conform to established quality, safety, and performance criteria as specified by the producer and automotive industry standards.

- Prevent Defects: Identify and detect any defects, discrepancies, or deviations as early as possible in the supply chain, reducing the risk of substandard or non-compliant items from reaching the production line or customers.

- Traceability: Establishing a traceable record of the inspection process, including documentation of test results, supplier information, and any corrective actions taken.

- Quality Assurance: Enhancing product quality and reliability, resulting in improved product quality, reduced rework, and defects.

- Supplier Integrity: Making suppliers accountable for the quality of the items they provide, foster supplier partnership and transparency in the supply chain.

- Continuous Improvement: Collecting data and analyzing them to identify areas for total quality improvement in product, performance, and processes.

In-Process Quality

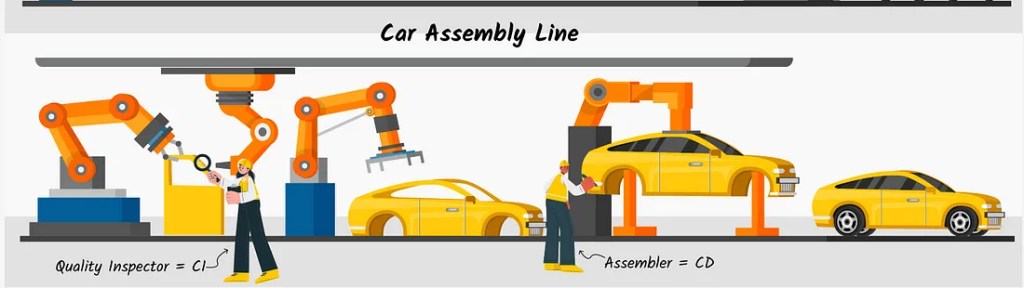

In-process inspection in automobile manufacturing is a comprehensive quality assurance practice that involves several activities aimed at ensuring the safety, quality, and reliability of vehicles at various stages of production. Some key activities in in-process inspection include:

- Component Verification: The process begins with inspection of individual components, ranging from engine parts to electronics and body panels. Each component is assessed for compliance with design specifications, including dimensional accuracy, material quality, and tolerances.

- Subassembly Assessment: As components are integrated into subassemblies, inspectors continue to evaluate the fit and functionality of these elements. This step ensures that structural integrity, alignment, and fastening meet the standards.

- Functional Testing: In-process inspection extends to comprehensive functional tests. Key vehicle systems, including engines, brakes, airbags, and electronic components, are tested to ensure they operate within performance and safety parameters. For instance, engine performance tests verify power and efficiency.

- Quality Control Checkpoints: Critical inspection points are strategically placed along the assembly line. Vehicles must meet specific quality criteria at these junctures before proceeding further. Inspections encompass areas such as torque settings, alignment, and paint quality.

- Continuous Monitoring: Real-time monitoring, often facilitated by automated systems and sensors, tracks vital parameters throughout the manufacturing process. This continuous vigilance ensures that deviations in temperature, pressure, torque, and other variables are detected promptly and addressed.

- Data-Driven Analysis: In-process inspection generates comprehensive documentation, including inspection reports and data on any deviations. This data is a valuable resource for tracking defects, identifying trends, and facilitating corrective and preventive actions. It is also instrumental in refining the production process.

- Operator Expertise: Skilled operators and inspectors are central to the success of in-process inspection. They are extensively trained to recognize and address issues effectively, maintaining the accuracy and consistency of the inspection process.

- Regulatory Adherence: The automobile industry is subject to rigorous safety and quality regulations. In-process inspection is designed to guarantee compliance with these standards, reducing the risk of safety recalls and legal liabilities.

- Traceability: Each component, subassembly, and vehicle is typically assigned a unique identifier, allowing for traceability. This traceability is essential for swift identification of affected vehicles and their components in the event of defects or recalls.

These activities collectively form a robust in-process inspection framework that is fundamental to automotive manufacturing. It ensures that vehicles adhere to strict standards at every step of production, minimizing the likelihood of defects reaching the end consumer and upholding the industry’s commitment to delivering high-quality, reliable, and safe vehicles.

Final Inspection

Final inspection in automobile manufacturing is a crucial stage before the vehicles are released to the market. This process serves as the ultimate checkpoint to ensure that each vehicle meets stringent safety, performance, and automotive industry quality standards.

Final inspection involves a thorough examination of the fully assembled vehicle, encompassing both exterior and interior components. Skilled inspectors will assess various aspects, including paint quality, panel alignment, interior fit and finish, and the proper functioning of all critical and safety related systems such as brakes, lighting, and electronics.

Key elements of final inspection include:

- Visual Assessment: Inspectors scrutinize the vehicle’s exterior and interior for any defects, imperfections, or deviations from design specifications. This includes checking for consistent paint quality, the absence of scratches or dents, and ensuring all interior components are properly fitted.

- Functional Testing: Comprehensive functional tests are conducted to ensure that all critical systems operate as intended. This includes assessing the performance of the engine, transmission, brakes, suspension, and safety features. Any discrepancies are addressed promptly.

- Road Testing: In many cases, vehicles undergo road tests to evaluate their handling, steering, and overall performance under real-world conditions. This phase helps identify any issues that might not be apparent during stationary inspection.

- Quality Control Documentation: Detailed records and inspection reports are generated at this stage, documenting any deviations, defects, or actions taken to rectify issues. These documents are essential for traceability and post-production analysis.

- Regulatory Compliance: Final inspection ensures that the vehicle complies with all safety, environmental, and quality regulations set by regulatory bodies and industry standards.

- Customer Satisfaction: Ultimately, the goal of final inspection is to deliver a vehicle that meets or exceeds customer expectations in terms of quality, safety, and performance.

Proper steps and system in final inspection is key to maintaining a manufacturer’s reputation for delivering and ensuring high-quality, reliable, and safe automobiles to the market. Final inspection not only help minimizes the risk of defects reaching consumers, but also ensures safety and satisfaction of vehicle owners through a robust and systematic system.

In short, the development of the key quality control stages comprising in-coming inspection, in-process quality control and final inspection are critical to the success of all automobile and its’ parts manufacturing companies. Continuous improvement of these systems can result in total customer satisfaction and make the processes effective and efficient.

if you need personal consultancy on this aspects, feel free to email me at shariyusof@gmail.com and for any online advises/discussions.

Leave a comment