Lean management, often referred to simply as “Lean,” is a management philosophy and set of practices that originated from the manufacturing sector, particularly Toyota Production System (TPS), but has since been applied to various industries and business processes. The primary goal of Lean management is to maximize value while minimizing waste.

Key principles and concepts of Lean management include:

- Value: Identifying and delivering what the customer perceives as value is a central focus of Lean. Value is defined as any activity or process that directly contributes to meeting customer needs.

- Value Stream: A value stream is the entire sequence of activities and processes required to create a product or provide a service, from the initial request to delivery. Lean management aims to optimize the value stream by eliminating non-value-adding activities.

- Flow: Lean seeks to establish a smooth and efficient flow of work, materials, and information through the value stream. This minimizes delays, bottlenecks, and other disruptions.

- Pull System: In a Lean system, production is based on actual customer demand. This means products or services are produced or provided only when the customer needs them, preventing overproduction and excess inventory.

- Continuous Improvement (Kaizen): A central tenet of Lean is the ongoing pursuit of improvement. Employees at all levels are encouraged to identify and address inefficiencies, reduce waste, and make incremental improvements to processes.- ALL PROCESSES MUST BE OBSERVED EVENTUALLY MAKING ALL OF THEM LEAN – MINIMUM WASTE OR NO WASTE

- Just-in-Time (JIT): JIT is a method of production scheduling where materials and components are delivered to the production line or service process just in time for their use. This reduces inventory and associated costs.

- Respect for People: Lean management places a strong emphasis on respecting and involving employees. Workers are seen as valuable sources of knowledge and creativity, and their input is sought for process improvement.

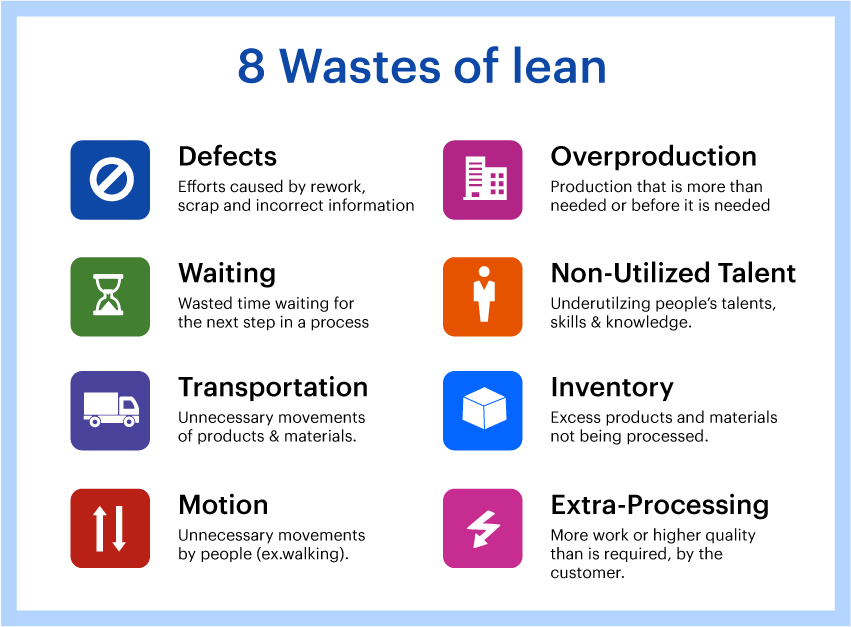

- Elimination of Waste (Muda): Lean identifies various forms of waste that need to be eliminated, including overproduction, waiting, unnecessary transportation, excess inventory, overprocessing, defects, and underutilized employee skills (referred to as the “7 wastes”) – THIS IS THE MOST IMPORTANT CONCEPT TO UNDERSTAND AND FOR EVERYONE TO IMPLEMENT AT ALL LEVELS

Lean management can be applied in various settings beyond manufacturing, including healthcare, software development, construction, and service industries. The Lean principles are versatile and can lead to increased efficiency, improved quality, cost reduction, and enhanced customer satisfaction when properly implemented.

Implementing Lean management principles in universities can lead to improved efficiency, better resource utilization, and enhanced student and staff satisfaction. Here are some steps to consider when implementing Lean in a university setting:

- Gain Leadership Buy-In: Start by getting support from university leadership. Top-down support is crucial for the success of any organizational change, including Lean implementation.

- Identify Stakeholders: Identify key stakeholders within the university community, including faculty, staff, and students. Involving all relevant parties is important for a successful implementation.

- Training and Education: Provide training and education on Lean principles to all staff members. This can be done through workshops, seminars, or online courses. Ensure everyone understands the core Lean concepts.

- Value Stream Mapping: Begin by mapping out the value streams in various processes, such as student enrollment, academic program development, or financial management. Identify areas where waste and inefficiencies exist.

- Eliminate Waste: Focus on eliminating waste in the processes. Common forms of waste in universities might include redundant paperwork, delays in approvals, and unnecessary bureaucracy. Streamline processes to remove these inefficiencies.

- Standardization: Develop standardized processes for common activities, like course registration, grading, or procurement. Standardization can reduce errors and make processes more predictable.

- Visual Management: Use visual management tools such as Kanban boards or Gantt charts to make the status of ongoing projects or processes easily visible to all stakeholders.

- Continuous Improvement: Encourage a culture of continuous improvement. Establish regular improvement cycles where teams review and optimize their processes. This could be through regular meetings, workshops, or online platforms for sharing improvement ideas.

- Feedback Loops: Establish feedback loops for students and staff to report issues and provide suggestions for improvement. Their feedback is invaluable in identifying areas for enhancement.

- Technology Integration: Leverage technology to automate and improve processes. Implementing an efficient Student Information System (SIS) or Learning Management System (LMS) can streamline many academic processes.

- Resource Optimization: Ensure optimal use of resources, both human and physical. This includes classroom and facility utilization, staffing levels, and resource allocation.

- Respect for People: Encourage collaboration and participation. Empower faculty and staff to take ownership of their processes and encourage them to suggest improvements.

- Key Performance Indicators (KPIs): Establish KPIs and metrics to measure the effectiveness of Lean initiatives. Regularly monitor and report on these metrics to gauge progress.

- Pilot Projects: Begin with small pilot projects to test Lean methodologies. Once you see success, expand Lean practices to other areas of the university.

- Celebrate Success: Recognize and celebrate the successes and improvements achieved through Lean initiatives. This helps maintain motivation and enthusiasm among staff and faculty.

Implementing Lean in a university requires time, effort, and patience, but it can lead to significant improvements in operational efficiency and the overall student experience. It’s important to tailor Lean strategies to the specific needs and challenges of the university environment.

Lean management relies on a variety of tools and techniques to help organizations identify and eliminate waste, improve processes, and optimize efficiency. Here are some of the most commonly used tools in Lean management but must be adapted for university setting:

- Value Stream Mapping (VSM): VSM is a graphical tool used to visualize and analyze the steps and information flow required to deliver a product or service to a customer. It helps identify areas of waste and inefficiency in the value stream.

- 5S: 5S is a workplace organization method that stands for Sort, Set in order, Shine, Standardize, and Sustain. It is used to create an organized, clean, and efficient work environment.

- Kaizen Events: Kaizen, which means “continuous improvement” in Japanese, involves short, focused events or workshops aimed at improving specific processes or areas of an organization. It often involves cross-functional teams.

- Kanban: Kanban is a visual management system that uses cards or other visual signals to control the flow of work. It’s commonly used in production and service processes to maintain a smooth flow of work and prevent overproduction.

- Poka-Yoke: Poka-Yoke, also known as mistake-proofing, is a technique that involves designing processes or tools in a way that prevents errors and defects from occurring.

- Just-in-Time (JIT): JIT is a method that involves producing or delivering products and services only when they are needed, reducing excess inventory and waste.

- Standard Work: Standard Work documents and standardizes the best-known way to perform a particular task or process, making it easier to maintain consistency and identify improvements

- A3 Problem Solving: The A3 report is a structured problem-solving tool that uses a single sheet of paper to document a problem, its root causes, potential solutions, and action plans.

- Visual Management: Visual management uses visual cues, such as charts, graphs, and displays, to make information readily available to employees, helping them understand the status of processes and identify problems.

- Gemba Walks: Gemba refers to the place where work happens. Gemba walks involve managers and leaders going to the workplace to observe and understand the actual work processes and engage with employees to identify areas for improvement.

These tools are used depending on the needs and suitability. They are often used in combination to address specific issues within an organization. Essentially we want to streamline all our processes and to identify and remove wastes as much as possible. Remove MUDA, MURI and MURA

ALL THESE ARE CHAPGPT GENERATED AND REVISED BY AUTHOR

Leave a comment