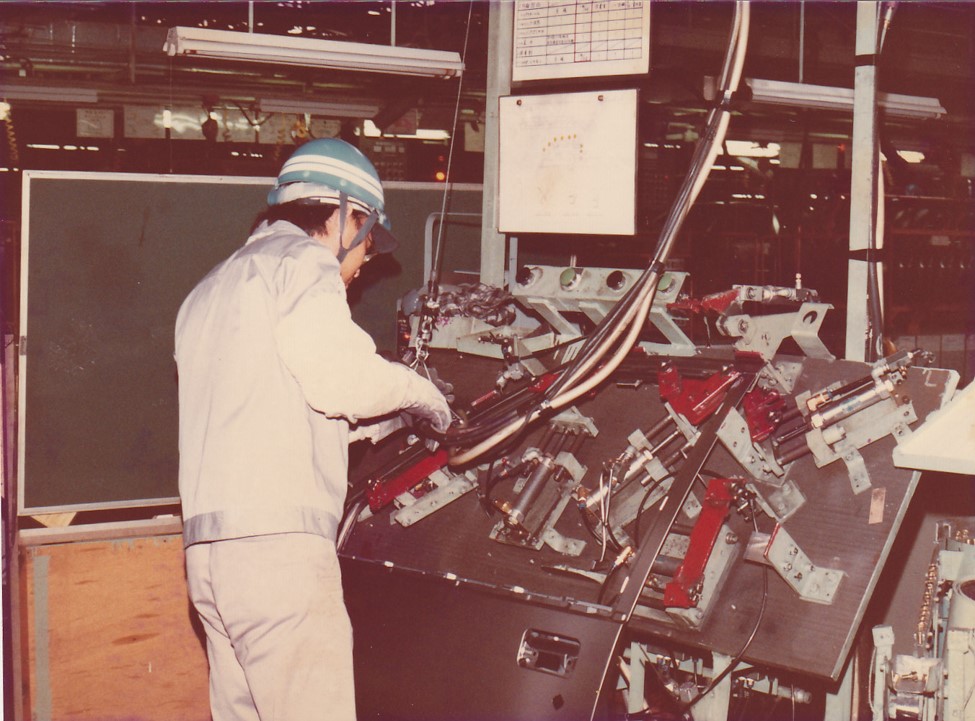

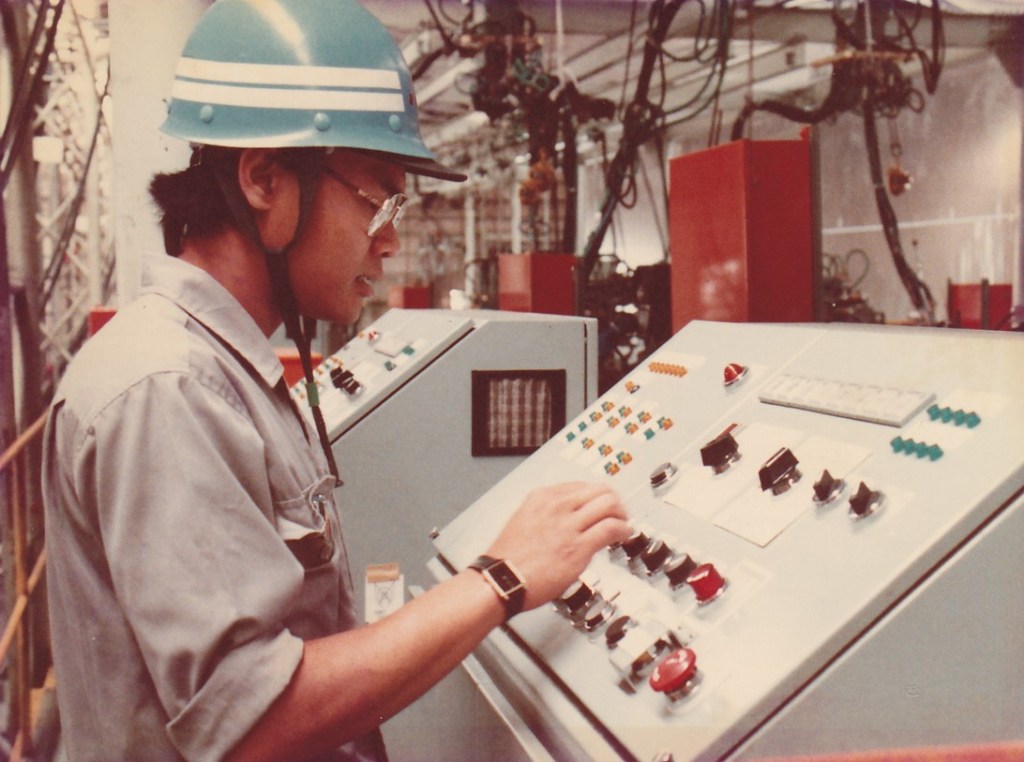

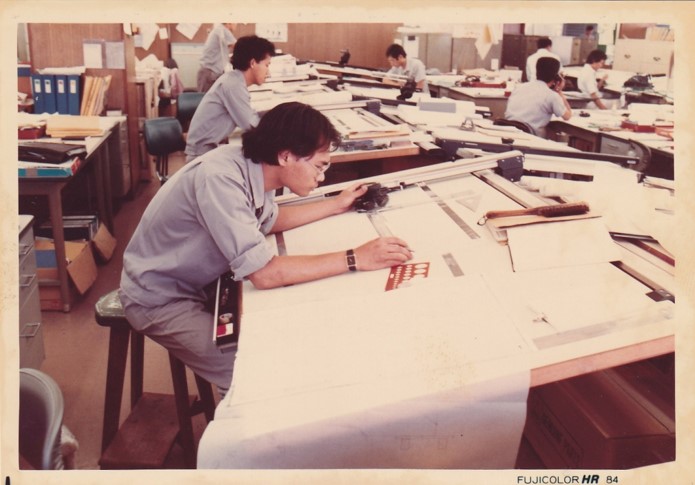

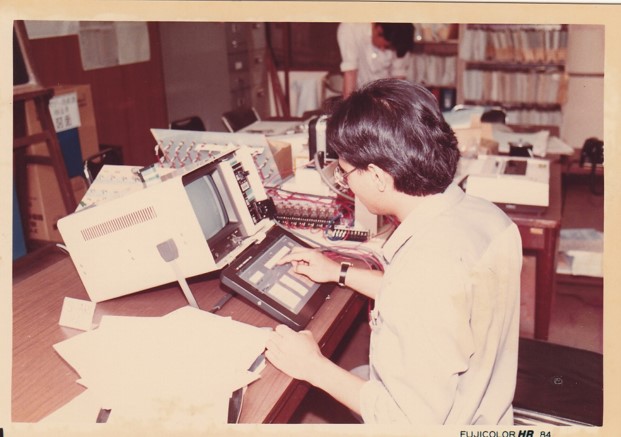

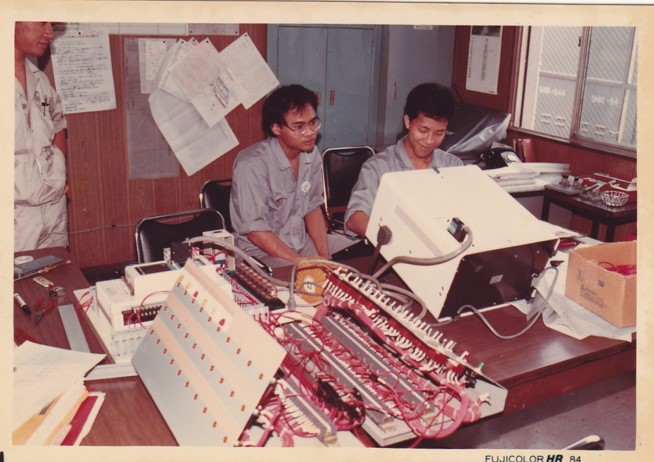

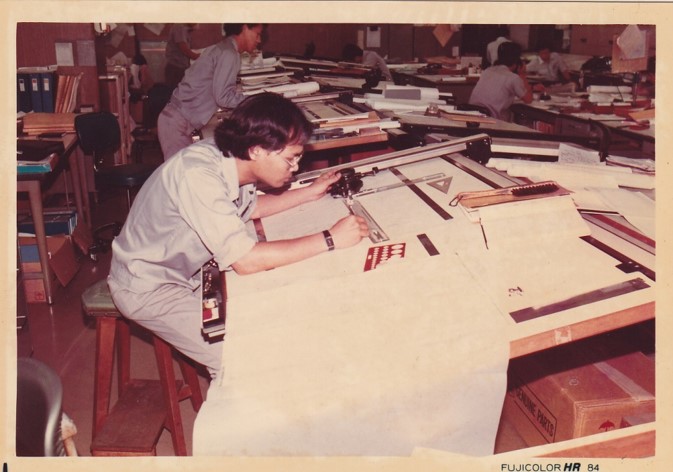

Today I was interviewed by a group of final year students majoring in Property Management, UTM, as part of their course requirement I believe. I did not how and where they got my name. However, the interview went on very well for a bit over one hour. First, I was asked about my background. I have also written in my About section of this blog. I told them almost similar things, but elaborated my experience after graduating and involvement in Proton. I told them that I had (or we the Japan Trainees) had to learn car technology in Nihon-Go and transfer that knowledge to Malaysians upon completion of training in Mizushima in 1993-84, in the company before we can make the car. I shared my experience on starting up Proton from the early stage of factory construction, body assembling shop equipment such as welding guns, transfer equipment, jigs and assembling machines installation, commissioning, handling and until mass production. It was tough, really. Hemming jigs for the doors, trunk lid, and hood assemblies. Once mass production commences in March 1984, as body assembling engineers we (me, Aris and Sorihan) had to make sure production will be able to start everyday without fail, and to resolve all the delivery, quality, production volume targets, maintenance of equipment are well coordinated and with support from other departments. It was such a wide and valuable experience that I acquired for over 6 years. And this was working with Japanese Technical Advisors/counterparts, and especially my respected sensei, Yoji Kurozumi san, who helped shape my work ethics, my Japanese way of thinking, the desired responsibilities and attitudes as a worker, leader and teacher. Then, I told them also that I was transferred to the Quality Control department in late 1987 to the Purchased Parts Inspection Section responsible to localize KD parts. In my case, I was assigned to Trim and Rubber Parts in the final assembling. So, from welding I had to learn the parts installed in final assembling such as Seat assemblies, Headlining, Door Trim, all the Rubber hoses, radiator , bypass hoses, exhaust hanger, silencers, and many others. In QC, I realized that it was such as enormous responsibility to ensure and assure that all parts comply and meet the specifications, especially safety and functional related parts and components. The challenge in developing vendors capable of producing the newly localised radiator hoses by Fudex Rubber was tremendous. I had to teach the vendors on setting up an inspection system and this made me understand the concept of Supplier Partnership where not only we assist them to build quality and take action when defects are passed unintentionally to us, but all the spectrum of supplier quality management such as supplier audit, supplier improvement, supplier ranking, and suppler assessment/selection. You can imagine how this really help shape my philosophy of quality and total quality and the Japanese management system of QCD.

I shared my academic journey as lecturer in UTM to the students as well beginning with acquiring master and later my PhD degrees. I told them that PhD is the hardest of them all. Doing PhD during late 90s means little access to what we have today of online databases and journal papers at your finger tip or touch of a screen. During those days, we had to move out of the house and go do it. Those pursuing research program had to physically go to libraries and use CD Databases, Microfilm PhD or published material and the printed Journals papers, conferences, reports, and others. It was a challenge. Despite these conditions, I managed to complete my PhD in three years 2 months (with corrected final thesis submission). It looks easy, but I believe all those doing PhD will testify that PhD is not easy. Thank God, I survived.

The students asked my what was my ingredients to success in my career and life.

I was brought up by my father who was an English and History teacher and my mother a midwife (still living at 80 today) who are very strict and disciplined. In my early childhood (around 6 or 7 years old), my parents bought me both Science Encyclopedia and Britannica (and it costs them a lot – and I know that my late father had to borrow and pay them by installments) . At an early age, I had already seen the world map, I was already reading about countries history, population, life, cultures, and many other things albeit not understand everything fully. It started to inspire to study and especially my interests in Science and Technology. It also open up my mind to appreciate the diverse culture, and peoples of the world. I then went to SMSJ, and learnt more new things. To cut the story short, after MCE I was offered to study abroad. I looked up in the Encyclopedia and found Chemical Engineering and Industrial Engineering as good areas to study and my ambition to be an engineer. In Form 5, Chemistry was actually my favorite subject and I put CE as my first choice and IE as my second choice for the application. Eventually, I was selected by the Ministry of Education to study IE in United States. I have never regretted the field that I studied.

SO, I have not answered the question how to succeed. Most of the answers are already shared above, if you can pick up between the lines.

Some of the many ways to be successful (in life). My answer to the students were:

- work hard and work harder

- work hard but work smart (smart here does not mean cheating) : You are cheating yourself when you think you cheat other people, eventually people will know that you don’t have the qualification, the degree, the success factors… very easy – just talk to the person and ask him few questions..

- study hard, especially on those subjects that you want to be an expert in

- keep on studying harder – expand new area of knowledge e.g. I.R.4.0

- learn new skills when you need to do so and not before it is too late..

- just do it – don’t wait for perfection to do things, and Kaizen

- perseverance – means continuously make effort to do it and improve

- do not procrastinate – don’t waste time by postponing what you can do now .. see No. 6 above

- solve and overcome problems not run away from problems

- create new opportunities (for new graduates – invent your own jobs)

- do more than what employer ask you to do

- think long term impact and effect – do not do things for the short term only

- for Muslims (Work hard with sincerely and intention to be rewarded in hereafter)

Sha’ri M Yusof, 7 Nov 2020, Saturday

Acknowledgement

Thank you to Khoo Chao Yee, Tan Aiy Li, Pang Chen Tay, Lim Min Qi, and Sook Yee [all from UTM] (hope I got your names correct) : ALL From Segamat and incidentally my late father(1934-2007) was also from Segamat.

Leave a comment